Space Systems Testing for ML

Business Context: Hyper-velocity impact testing is required to generate ground truth data for analytical and machine learning representations of novel spacecraft shielding.

Problem Statement: Acquire high-fidelity experimental data to validate physics-informed ML models and improve predictive accuracy of spacecraft MMOD protection systems.

My Role: Led design, execution, and analysis of hyper-velocity test campaigns. Coordinated with NASA test facilities, suppliers, and internal engineering teams to ensure data quality and relevance for system verification ML applications.

Deliverables & Implementation:

- Designed and manufactured hardware test articles representing Blue Origin spacecraft architectures.

- Directed test campaigns at NASA facilities, capturing high-speed impact dynamics and material response data.

- Processed and curated datasets for training physics-informed neural networks and validating ballistic limit equations and correlated to shock-physics simulations of hyper-velocity impacts

- Integrated results into system design loops, feeding back into ML models and vehicle shielding architecture.

Impact: Produced first-of-kind experimental datasets enabling ML models to outperform legacy ballistic equations by ~40%, directly informing spacecraft shielding design and reducing system mass while maintaining crew safety.

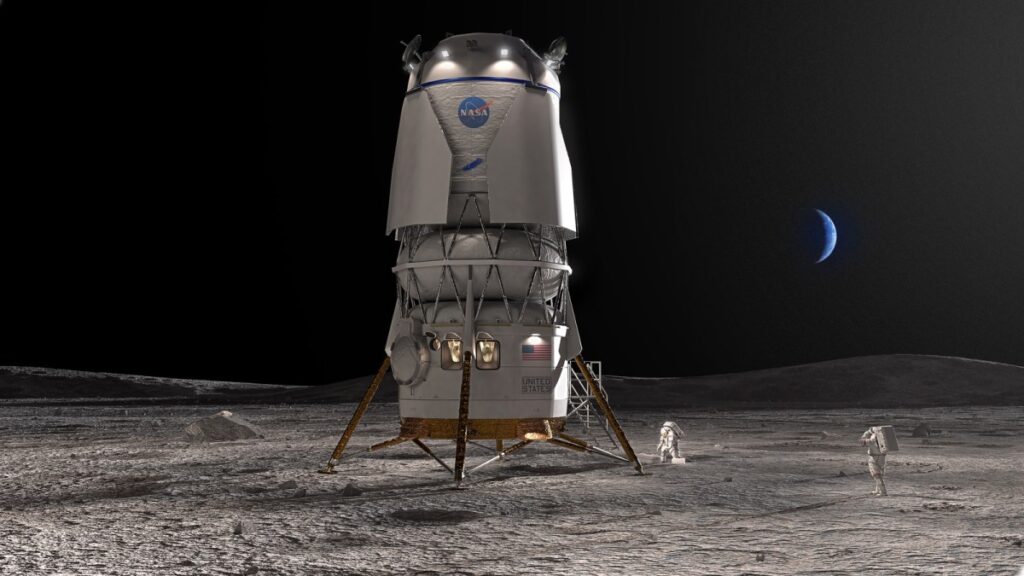

Composite Meteoroid & Orbital Debris Shielding for NASA Artemis

Business Context: NASA’s Artemis program requires advanced shielding to protect crewed lunar missions from meteoroid and orbital debris (MMOD) threats. Composite MMOD shields offer major mass savings compared to legacy metallic designs, but require new validation for flight certification.

Problem Statement: Design, analyze, prototype, and validate composite-based MMOD shielding architectures that meet NASA survivability requirements while minimizing vehicle mass and integration complexity.

My Role: Sole MMOD lead responsible for shielding design strategy, from early trade studies through hardware prototyping, testing, and requirements negotiation with NASA. Provided technical guidance to program leadership and mentored junior design engineers.

Deliverables & Implementation:

- Testing: Directed hyper-velocity impact tests of composite materials, establishing ballistic performance baselines and validating analytical/ML models.

- Prototyping: Led design, build, and iteration of composite shielding prototypes to mature concepts for manufacturability and certification.

- Team Development: Mentored junior engineers in mechanical design, shielding design methods, simulation tools, and test planning, raising overall team capability.

- Innovation & Strategy: Pitched novel composite shielding approaches to program leadership, gaining buy-in for technology infusion.

- Customer Engagement: Authored design documentation and hazard reports; led NASA design reviews to adjudicate requirements and secure acceptance.

- Integration: Partnered with supply chain, finance, and manufacturing teams to ensure feasible, scalable production.

Impact: Demonstrated composite MMOD shielding that delivered a 46% assembly mass savings with a doubling in rated ballistic limit performance relative to the heritage baseline concept, while maturing prototypes, mentoring future engineers, and securing leadership support for innovative designs—ultimately improving vehicle performance and helping enable humans on the moon in 2029.